Understanding the Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Engine Performance

Related Articles: Understanding the Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Engine Performance

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to Understanding the Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Engine Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Understanding the Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Engine Performance

- 2 Introduction

- 3 Understanding the Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Engine Performance

- 3.1 The MAP Sensor: A Vital Link in the Engine’s Feedback Loop

- 3.2 How the MAP Sensor Works: A Detailed Look Inside

- 3.3 The Consequences of a Failing MAP Sensor: A Cascade of Engine Problems

- 3.4 Identifying the Symptoms of a Faulty MAP Sensor: A Guide for Early Detection

- 3.5 Troubleshooting a Suspected MAP Sensor Problem: A Step-by-Step Approach

- 3.6 Frequently Asked Questions (FAQs) about MAP Sensor Failure

- 3.7 Tips for Maintaining a Healthy MAP Sensor: Proactive Measures for Longevity

- 3.8 Conclusion: The MAP Sensor – A Silent Guardian of Engine Performance

- 4 Closure

Understanding the Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Engine Performance

The intricate dance of modern internal combustion engines relies on a symphony of sensors and actuators, each playing a vital role in ensuring smooth and efficient operation. Among these critical components, the Manifold Absolute Pressure (MAP) sensor stands as a silent guardian, providing essential data to the engine control unit (ECU) for optimal fuel delivery and ignition timing.

The MAP Sensor: A Vital Link in the Engine’s Feedback Loop

The MAP sensor, strategically positioned within the engine’s intake manifold, measures the absolute pressure of the air entering the cylinders. This pressure, a direct indicator of the volume of air being drawn into the engine, serves as a crucial input for the ECU. By accurately measuring this pressure, the MAP sensor allows the ECU to precisely determine the amount of fuel needed for combustion, ensuring optimal air-fuel ratios for maximum efficiency and power.

How the MAP Sensor Works: A Detailed Look Inside

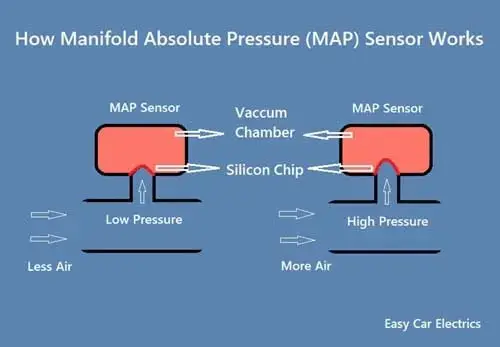

The MAP sensor itself is a relatively simple yet ingenious device. It typically comprises a diaphragm sealed within a chamber. As air pressure changes within the intake manifold, the diaphragm flexes, altering the resistance of a variable resistor. This change in resistance is then converted into a voltage signal that the ECU interprets.

The ECU, armed with this information, can make informed decisions regarding:

- Fuel Injection Timing: By adjusting the timing of fuel injection based on the air pressure, the ECU ensures that fuel is delivered at the optimal moment for efficient combustion.

- Fuel Injection Duration: The amount of fuel injected into the cylinders is directly proportional to the air pressure. The MAP sensor provides the ECU with the necessary data to determine the appropriate fuel injection duration for each cylinder.

- Ignition Timing: The ECU uses the MAP sensor data to adjust the ignition timing, ensuring optimal spark delivery for maximum combustion efficiency and power output.

The Consequences of a Failing MAP Sensor: A Cascade of Engine Problems

A malfunctioning MAP sensor can disrupt the delicate balance of the engine’s control system, leading to a range of performance issues:

- Poor Fuel Economy: An inaccurate air pressure reading can result in over- or under-fueling, leading to inefficient combustion and reduced fuel economy.

- Engine Misfire: Erratic fuel delivery due to a faulty MAP sensor can cause misfires, resulting in rough idling, engine hesitation, and reduced power.

- Increased Emissions: Incorrect air-fuel ratios can lead to increased emissions, potentially exceeding regulatory standards.

- Check Engine Light: A malfunctioning MAP sensor will trigger the check engine light, indicating a need for diagnosis and repair.

Identifying the Symptoms of a Faulty MAP Sensor: A Guide for Early Detection

While a failing MAP sensor can manifest in various ways, some common symptoms can serve as red flags:

- Engine Stalling: A sudden loss of engine power or stalling, particularly at idle, can be a sign of a faulty MAP sensor.

- Rough Idling: Uneven engine operation at idle, characterized by vibrations or shaking, could indicate a malfunctioning MAP sensor.

- Hesitation During Acceleration: A delay in engine response when accelerating, resulting in sluggish performance, could be attributed to a faulty MAP sensor.

- Black Smoke from Exhaust: Excessive black smoke from the exhaust can indicate a rich fuel mixture, potentially caused by a faulty MAP sensor.

Troubleshooting a Suspected MAP Sensor Problem: A Step-by-Step Approach

If you suspect a MAP sensor issue, a systematic troubleshooting approach can help pinpoint the problem:

- Visual Inspection: Start by inspecting the MAP sensor for any physical damage, corrosion, or loose connections.

- Check for Vacuum Leaks: A vacuum leak in the intake manifold can affect the MAP sensor readings. Check for any visible leaks and ensure all vacuum hoses are securely connected.

- Use a Scanner: A diagnostic scanner can read the MAP sensor data and compare it to the manufacturer’s specifications. This can help identify any discrepancies or errors.

- Perform a Vacuum Test: A vacuum test can assess the vacuum pressure within the intake manifold, providing valuable information about potential issues.

- Replace the MAP Sensor: If all other troubleshooting steps fail to identify the problem, replacing the MAP sensor is often the most effective solution.

Frequently Asked Questions (FAQs) about MAP Sensor Failure

1. What are the common causes of MAP sensor failure?

MAP sensor failure can be caused by several factors, including:

- Physical Damage: The sensor can be damaged by impact, heat, or corrosion.

- Contamination: Dirt, oil, or other contaminants can interfere with the sensor’s operation.

- Electrical Problems: Issues with the sensor’s wiring or connections can lead to malfunction.

- Wear and Tear: Over time, the sensor’s internal components can wear out, leading to inaccurate readings.

2. How often should a MAP sensor be replaced?

MAP sensors typically have a lifespan of several years. However, their longevity can be affected by factors such as driving conditions and maintenance practices. It’s recommended to replace the sensor if it exhibits any signs of malfunction or if it’s nearing the end of its expected lifespan.

3. Can I drive with a faulty MAP sensor?

While it’s technically possible to drive with a faulty MAP sensor, it’s not recommended. A malfunctioning sensor can lead to a range of performance issues, including reduced fuel economy, engine misfires, and increased emissions. It’s best to have the sensor repaired or replaced as soon as possible.

4. Can I reset the check engine light after replacing the MAP sensor?

Once the MAP sensor is replaced, the check engine light should be reset. This can be done using a diagnostic scanner or by disconnecting the battery for a few minutes. However, it’s important to note that the check engine light may not always clear immediately after replacing the sensor. The ECU may need to run through a few driving cycles to confirm that the issue has been resolved.

Tips for Maintaining a Healthy MAP Sensor: Proactive Measures for Longevity

While MAP sensors are generally robust components, proactive maintenance can extend their lifespan and prevent premature failure:

- Regularly Inspect the Sensor: Visual inspection of the sensor for signs of damage, corrosion, or contamination should be part of routine maintenance.

- Keep the Intake Manifold Clean: A clean intake manifold helps prevent contaminants from reaching the MAP sensor.

- Avoid Exposing the Sensor to Extreme Temperatures: Excessive heat or cold can damage the sensor.

- Use Quality Parts: When replacing the MAP sensor, opt for high-quality, OEM-approved parts to ensure optimal performance and longevity.

Conclusion: The MAP Sensor – A Silent Guardian of Engine Performance

The MAP sensor, though often overlooked, plays a crucial role in maintaining the delicate balance of the engine’s control system. Its accurate measurement of air pressure enables the ECU to make informed decisions about fuel delivery and ignition timing, ensuring optimal performance, fuel economy, and reduced emissions. By understanding the importance of the MAP sensor and its potential for failure, drivers can proactively identify and address any issues before they escalate into major engine problems.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Engine Performance. We thank you for taking the time to read this article. See you in our next article!